- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

In the highly specialized world of controlled environments, the selection of building materials is not merely a matter of cost or aesthetics; it is a critical decision that directly impacts product quality, research integrity, and operational safety. Cleanrooms, essential in industries like pharmaceuticals, biotechnology, microelectronics, and healthcare, demand wall and partition systems that are exceptionally durable, easy to clean, and inherently resistant to contamination. Among the premier solutions available today are Smooth White FRP Panels. These panels offer a seamless, non-porous surface that stands up to the rigors of cleanroom maintenance. Available in a range of thicknesses, including 1.2mm, 1.5mm, 2mm, and 3mm, these FRP panel smooth white products provide unparalleled versatility for constructing high-performance cleanroom walls and ceilings. This comprehensive guide will explore the unique benefits of these panels, their specific applications, and how their different thicknesses cater to various cleanroom requirements.

Fiberglass Reinforced Plastic (FRP) panels have long been recognized as a superior building material for demanding environments. The smooth white frp variant, in particular, is engineered to meet the exacting standards of cleanrooms and other hygienic facilities. But what exactly makes this material so ideal?

The effectiveness of an FRP panel smooth white for cleanroom applications stems from its fundamental properties:

Non-Porous Surface: Unlike materials like drywall or wood, the surface of a smooth FRP panel has no microscopic holes or pores. This prevents moisture, bacteria, mold, and chemical spills from being absorbed, making it incredibly easy to sterilize and maintain.

High Impact Resistance: FRP is a remarkably tough material. It can withstand accidental bumps from equipment and carts without denting, cracking, or shattering, ensuring the long-term structural integrity of the cleanroom walls.

Exceptional Durability and Longevity: These panels do not corrode, rot, or delaminate easily. They resist the damaging effects of harsh cleaning agents and industrial chemicals, ensuring a long service life with minimal maintenance.

Compliance with Hygiene Standards: The bright, reflective smooth white finish not only promotes a clean and bright appearance but also helps in identifying contaminants quickly. This makes the frp panel for cleanroom walls compliant with stringent regulatory standards from bodies like the FDA, USDA, and ISO.

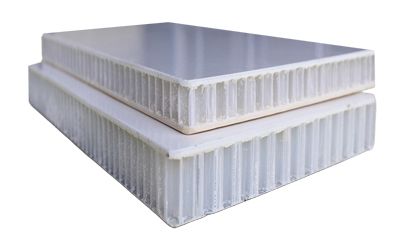

A significant advantage of using our FRP panel smooth white for walls is its exceptional adaptability as a facing material for composite structures. By bonding these durable sheets to various core materials, manufacturers can create high-performance sandwich panels that offer superior insulation, structural strength, and weight characteristics tailored to specific project needs.

Our FRP panel smooth white is designed for perfect adhesion with a wide array of core materials, making it the ultimate choice for custom cleanroom wall partition solutions. These core materials include:

PU Foam (Polyurethane): Known for its excellent thermal insulation properties and good structural rigidity. Sandwich panels with a PU foam core are ideal for cleanrooms requiring strict temperature control.

XPS Foam (Extruded Polystyrene): Offers high compressive strength and superior moisture resistance compared to other foams, making it a robust choice for panels that may be subject to physical stress.

EPS Foam (Expanded Polystyrene): A cost-effective insulation core that provides good thermal performance and is lightweight, facilitating easier installation.

Plastic PP Honeycomb: This core provides an outstanding strength-to-weight ratio. It is also completely resistant to moisture and chemicals, making it perfect for creating very lightweight yet incredibly strong partitions that are easy to handle and install.

Aluminum Honeycomb: For applications demanding the ultimate in structural strength and flatness while remaining exceptionally lightweight, aluminum honeycomb is the premium choice. Panels with this core are used in high-specification cleanrooms where absolute stability is paramount.

This versatility allows designers and builders to select the perfect combination of FRP panel smooth white and core material to achieve the desired balance of insulation, strength, weight, and cost for any cleanroom wall partition project.

The thickness of the FRP panel smooth white is a critical factor that influences the panel's rigidity, impact resistance, and overall performance. Our range of 1.2mm, 1.5mm, 2mm, and 3mm thicknesses ensures there is an optimal solution for every application, from low-traffic areas to high-impact zones.

The 1.2mm frp panel smooth white represents the entry point into high-performance wall cladding, offering a superb balance of performance and cost-effectiveness. It is perfectly suited for:

Cleanroom ceilings and upper wall sections that are less prone to direct impact.

Environments where budget is a primary concern, but hygiene cannot be compromised.

Applications where the panel will be fully supported by a sturdy substrate or framework.

While thinner, the 1.2mm frp panel smooth white still provides the essential non-porous, easy-to-clean surface that defines a high-quality frp panel for cleanroom environments.

Arguably the most popular and widely specified thickness, the 1.5mm frp panel smooth white is the industry standard for vertical wall applications in cleanrooms. It strikes an ideal balance between durability, flatness, and cost. Key applications include:

Primary wall partitions in pharmaceutical and electronics cleanrooms.

Healthcare facilities, including operating rooms and laboratories.

Food and beverage processing areas where daily wash-downs are required.

The 1.5mm frp panel smooth white provides enhanced rigidity over the 1.2mm variant, reducing the risk of oil-canning (a wavy appearance) and offering better resistance to the occasional bump or scrape, making it the go-to frp panel for cleanroom walls.

For areas that experience more frequent contact or require a more robust feel, the 2mm frp panel smooth white is the superior choice. The additional thickness translates to:

Significantly higher impact resistance, ideal for areas with moving equipment or high traffic.

Superior surface flatness and a more substantial, premium appearance.

Excellent performance in applications where the panel may need to span wider supports without a backing substrate.

The 2mm frp panel smooth white is often specified for lower wall sections, corridors, and areas where durability is a top priority, ensuring the frp panel smooth white for cleanroom maintains its pristine condition for years.

At the top of the range, the 3mm frp panel smooth white offers maximum rigidity, impact resistance, and structural integrity. This thickness is designed for the most demanding applications, such as:

Areas with a high risk of heavy impact.

Specialized industrial cleanrooms where extreme durability is non-negotiable.

Applications where the panel itself contributes significantly to the structural strength of the partition system.

Choosing the 3mm frp panel smooth white is an investment in long-term performance, virtually eliminating concerns about damage and ensuring the frp panel for cleanroom walls can withstand the toughest conditions.

The practical benefits of using an FRP panel smooth white for walls extend beyond its material properties to the installation and long-term maintenance phases.

Installing our FRP panel for cleanroom is a straightforward process. The panels can be easily cut with standard woodworking tools and are installed using a variety of methods, including:

Adhesive bonding directly to a stable substrate (e.g., gypsum board, plywood, or existing walls).

Mechanical fastening with rivets or screws with color-matched caps for a clean, seamless look.

Integration into proprietary framing systems designed for modular cleanroom construction.

The lightweight nature of the thinner panels, like the 1.2mm frp panel smooth white, further simplifies handling and reduces labor time and costs.

The primary purpose of an frp panel for cleanroom walls is to maintain a contaminant-free environment, and the smooth white frp surface makes this task remarkably simple. The non-absorbent surface can be repeatedly cleaned and disinfected with aggressive chemicals, high-pressure sprays, and steam without degrading. The bright white color helps in maintaining high light levels within the cleanroom, reducing energy costs, and also makes any dirt or residue immediately visible, ensuring thorough cleaning.

Selecting the appropriate wall material is a foundational step in designing an effective and reliable cleanroom. The FRP panel smooth white for cleanroom applications represents a perfect synergy of hygiene, durability, and design flexibility. From the cost-effective 1.2mm frp panel smooth white to the ultra-robust 3mm frp panel smooth white, there is a thickness precisely engineered for every need and budget. Furthermore, its unique compatibility with core materials like PU, XPS, EPS, PP Honeycomb, and Aluminum Honeycomb allows for the creation of custom sandwich panels that deliver specific performance characteristics. By choosing the right frp panel for cleanroom walls, you are not just constructing a partition; you are investing in a system that safeguards your processes, your products, and your reputation for years to come.

Contact us:

Email: lzpanels@163.com

WhatsApp/Wechat: 008613702432446