- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

In the world of modern industrial manufacturing and specialized transportation, the choice of materials is paramount. Among the most versatile and essential components are Glass Fiber Reinforced Plastic (GFRP) sheets and coils. Specifically engineered for demanding applications, GFRP sheet and GFRP sheet coil products offer an unparalleled combination of strength, durability, and lightweight properties. This comprehensive guide delves into the critical role of GFRP coil for sandwich panel and GFRP coil for composite panel constructions, with a focused look at the popular 1.2mm GFRP coil, 1.5mm GFRP coil, and 2mm GFRP coil thicknesses, available in both standard white GFRP coil and grey GFRP coil finishes. Designed to be laminated onto insulating cores like XPS (Extruded Polystyrene), PU (Polyurethane), and EPS (Expanded Polystyrene), or honeycomb structures, these materials form the robust outer skins of refrigerated trucks (reefers), dry freight vans, and advanced architectural panels. We will explore their specifications, benefits, and applications in detail.

A GFRP sheet coil is a continuous, factory-produced roll of Glass Fiber Reinforced Plastic. It is manufactured by embedding high-strength glass fibers within a thermosetting resin matrix, typically polyester or vinylester, resulting in a composite material with exceptional mechanical properties. This coil format allows for efficient, large-scale, and automated production of composite sandwich panels. The key advantages of using a GFRP coil for composite panel production include consistent quality, reduced waste, and the ability to create long, seamless panel lengths, which is crucial for trailer and container manufacturing. Unlike single sheets, the coil form facilitates a continuous lamination process, significantly enhancing productivity for panel makers.

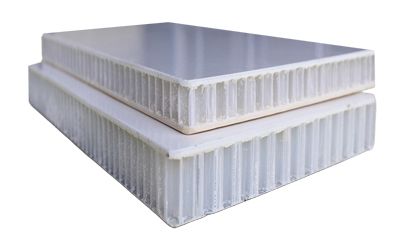

A composite sandwich panel is a structure consisting of three layers: two thin, strong, and stiff outer skins bonded to a thick, lightweight, and low-density core. The GFRP sheet acts as the definitive outer skin or facing material. When a GFRP coil for sandwich panel is unrolled and bonded to cores like XPS, PU, EPS, or honeycomb, it creates a synergistic effect. The GFRP skin carries the bending and in-plane loads, providing tensile and compressive strength, impact resistance, and protection from the environment. The core material, meanwhile, stabilizes the skins, carries shear loads, and provides exceptional thermal insulation—a non-negotiable requirement for temperature-controlled transportation. This combination results in a structure that is remarkably strong and rigid yet lightweight, a critical factor for payload efficiency in transport vehicles.

The thickness of the GFRP sheet coil is a primary determinant of the final panel's mechanical performance, weight, and cost. Manufacturers offer standard gauges to suit different load-bearing requirements and applications.

1.2mm GFRP Coil: This is a popular choice for applications requiring an excellent balance between weight savings and performance. The 1.2mm GFRP coil provides sufficient stiffness, impact resistance, and surface quality for many standard-duty dry vans and interior linings. It is ideal where weight optimization is crucial without compromising structural integrity.

1.5mm GFRP Coil: Often considered the industry workhorse, the 1.5mm GFRP coil offers enhanced durability and rigidity over the 1.2mm variant. It is the preferred thickness for a vast majority of refrigerated truck and trailer exteriors, providing robust resistance to road debris, weather, and the physical demands of loading and unloading. It delivers an optimal performance-to-weight ratio for demanding logistics applications.

2mm GFRP Coil: For the most severe service conditions, the 2mm GFRP coil is the go-to specification. This thicker skin delivers maximum impact resistance, puncture resistance, and overall panel stiffness. It is specified for heavy-duty applications, high-traffic areas, or where the panel might face exceptional mechanical stress. Panels made with 2mm GFRP coil are built to last in the toughest environments.

The color of the GFRP sheet is not merely an aesthetic choice; it has significant functional implications. The two most common and practical options are white GFRP coil and grey GFRP coil.

Benefits of White GFRP Coil: A white GFRP coil is the standard for refrigerated transportation. Its high albedo (reflectivity) plays a vital role in thermal management by reflecting solar radiation, thereby reducing the thermal load on the refrigeration unit. This leads to improved energy efficiency and lower operating costs. The bright, clean appearance is also associated with hygiene and is often preferred for food-grade transport.

Benefits of Grey GFRP Coil: A grey GFRP coil offers a more neutral, industrial aesthetic and is a common choice for dry freight vans and certain architectural applications. It shows less visible dirt and wear over time compared to brighter whites. The grey pigment also provides consistent UV stability, protecting the resin matrix from long-term degradation caused by sunlight exposure.

Both white and grey GFRP coil products are typically manufactured with a high-gloss, smooth gel-coat finish on one side. This finish creates an impervious, non-porous surface that is easy to clean, chemically resistant, and provides an excellent substrate for painting or branding if required.

The core material is the heart of the sandwich panel, defining its insulating properties. The GFRP sheet coil is laminated to these cores under controlled heat and pressure to create a permanent, high-strength bond.

XPS (Extruded Polystyrene): Known for its high compressive strength and excellent long-term thermal resistance (R-value), XPS is a closed-cell foam that is highly resistant to moisture absorption. This makes panels with XPS cores and GFRP skins ideal for refrigerated applications where humidity control and consistent insulation are critical.

PU (Polyurethane): PU foam is widely used for its superior insulation properties, offering one of the highest R-values per inch among common materials. It is typically poured in place and bonds exceptionally well to the GFRP sheet, creating a monolithic, strong, and highly efficient panel perfect for cold chain logistics.

EPS (Expanded Polystyrene): A cost-effective and lightweight option, EPS is a closed-cell foam with good insulating properties. Panels using EPS cores and GFRP coil for sandwich panel construction are often used in dry vans and some controlled-temperature applications where extreme insulation performance is not the primary driver.

For applications requiring extreme stiffness-to-weight ratios or specific mechanical properties, honeycomb cores (often aluminum, paper, or plastic) are used. Laminating a GFRP coil for composite panel onto a honeycomb core creates an ultra-light, incredibly rigid, and strong panel used in specialized transport, aerospace, and high-end architectural applications.

This is one of the most critical applications for 1.5mm and 2mm GFRP coil products, predominantly in white. The entire body of a refrigerated trailer or truck is typically constructed from large composite sandwich panels. The GFRP sheet exterior provides a durable, seamless, weatherproof, and easy-to-clean surface. Its resistance to corrosion, chemicals (like road salts), and impact is essential for withstanding harsh operating conditions. Paired with a PU or XPS core, the panel ensures maximum thermal efficiency to maintain precise internal temperatures for perishable goods, pharmaceuticals, and other temperature-sensitive products.

For non-refrigerated logistics, GFRP coil for sandwich panel is equally vital. Dry vans benefit from the material's strength, lightweight nature, and durability. Panels made with 1.2mm or 1.5mm grey GFRP coil offer a robust exterior that protects cargo from the elements. The smooth interior surface, when used as an interior lining, prevents damage to goods and is easy to maintain. The overall weight reduction compared to traditional materials like aluminum or steel directly translates into higher legal payload capacity and improved fuel economy for fleet operators.

Beyond transportation, the principles of composite panels are applied in architecture. GFRP sheet coil materials are used to create insulated wall and roof panels for cold storage warehouses, clean rooms, and industrial buildings. The material's aesthetic flexibility (through color and finish), insulation performance, and durability make it a compelling choice for modern construction.

Panels skinned with GFRP coil are significantly lighter than those made with steel or aluminum of comparable strength. This weight saving is a direct economic advantage in transportation.

GFRP sheet is inherently corrosion-proof, resisting rust, rot, and chemical attack. It maintains its structural integrity and appearance over a long service life, even in wet, salty, or chemically aggressive environments.

When seamlessly bonded to an insulating core, the GFRP sheet coil creates a monolithic, airtight envelope. This is paramount for minimizing thermal bridging and maintaining consistent internal temperatures in cold chain applications.

The use of GFRP sheet coil in a continuous lamination line allows for high-volume, automated production of sandwich panels with consistent quality, repeatable properties, and customizable lengths.

The non-porous, gel-coat finish of the GFRP sheet is easy to clean and disinfect, meeting hygiene standards for food transport. It does not require painting or regular anti-corrosion treatments.

In summary, the selection of the appropriate GFRP sheet coil—be it a 1.2mm GFRP coil, 1.5mm GFRP coil, or 2mm GFRP coil in white or grey—is a foundational decision in the design and manufacture of high-performance composite sandwich panels. Whether the end use is a refrigerated trailer traversing continents or a dry freight van on urban delivery routes, these materials provide the essential blend of strength, insulation, durability, and efficiency. The GFRP coil for sandwich panel and GFRP coil for composite panel applications represent a mature, proven technology that continues to be the material of choice for industries where reliability, payload, and thermal performance are measured on the bottom line. By understanding the specifications and applications outlined in this guide, manufacturers and designers can make informed choices to build lighter, stronger, and more efficient structures for the future of transportation and construction.

Contact us:

Email: lzpanels@163.com

WhatsApp/Wechat: 008613702432446