- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

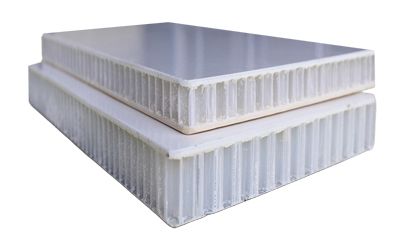

In the dynamic world of commercial transport and logistics, the quest for materials that offer durability, efficiency, and versatility is never-ending. At the heart of a transformative shift in truck body manufacturing lies a singular, potent solution: the solid fiberglass sheet. Specifically, the smooth fiberglass sheet available in precise, industry-tailored thicknesses such as smooth fiberglass sheet 1.2mm, 1.5mm, and 2mm, supplied in convenient coil form, is redefining how durable and lightweight composite panels are engineered. This isn't just another material option; it represents a foundational layer for innovation. Unlike multi-layered laminates, this single-ply, solid fiberglass sheet serves as the perfect, impervious skin. It is expertly designed to be adhesively bonded to core materials like XPS (Extruded Polystyrene), PU (Polyurethane) foam, or aluminum honeycomb, creating a hybrid composite panel that leverages the unmatched protective qualities of fiberglass with the core-specific advantages of lightness, thermal insulation, or supreme strength. This article explores this unique product from a novel perspective: as the critical, unifying "performance skin" that enables modular, superior truck panel construction, offering a fresh take on its role beyond a simple raw material.

Traditionally, composite panel construction involves balancing disparate material properties, often leading to compromises. The advent of the smooth FRP sheet in coil form introduces a paradigm shift. It is best understood not merely as sheeting, but as a continuous, rollable "performance skin." This smooth fiberglass sheet for composite panel application provides a consistent, high-quality outer surface that is permanently defended against the elements. Its single-layer, solid fiberglass sheet structure ensures there are no delamination points within the skin itself, offering inherent integrity from the start. When this robust skin is married to a functional core, the resulting panel achieves a synergy where the whole is exponentially greater than the sum of its parts. This approach allows manufacturers to treat the solid fiberglass sheet as a standard, reliable component—a performance baseline—upon which various core technologies can be applied to create specialized panels for different parts of a truck or for different operational requirements, all from the same foundational material.

A key to leveraging this material effectively lies in understanding the strategic implications of its available gauges. Each thickness—smooth fiberglass sheet 1.2mm, smooth fiberglass sheet 1.5mm, and smooth fiberglass sheet 2mm—serves a distinct purpose in the composite matrix.

The smooth FRP sheet 1.2mm represents the choice for ultimate weight optimization without sacrificing critical surface protection. This thin, yet remarkably strong gauge is ideal for applications where the composite panel is designed for maximum weight savings and where the structural loads are primarily borne by a high-strength core, such as a dense honeycomb. It provides a flawless, resistant outer surface that is waterproof and UV-stable, while adding minimal mass. Its flexibility in coil form also makes it excellent for panels with subtle curvatures.

Occupying the perfect middle ground, the smooth FRP sheet 1.5mm is the versatile workhorse for truck panel fabrication. It offers an enhanced stiffness and impact resistance compared to the 1.2mm variant, making it suitable for most wall and roof applications on truck bodies. This thickness of smooth fiberglass sheet provides a robust facing that can handle the rigors of daily operation, from freight loading to road debris, while still being efficiently bonded to insulating PU or XPS cores. It is often considered the default choice for its balance of performance, durability, and cost-effectiveness.

For areas requiring exceptional durability and puncture resistance, the smooth FRP sheet 2mm stands as the heavy-duty armor. This thickness is specified for high-wear zones such as truck floors, headboards, and side panels in demanding environments (e.g., construction, mining). The smooth fiberglass sheet 2mm delivers a tremendously tough outer shell that protects the core material from extreme mechanical stress. When combined with a core, it creates a panel capable of withstanding impacts that would compromise lesser materials, ensuring long-term structural integrity.

The provision of these sheets in coil form is a logistical and manufacturing breakthrough that deserves its own focus. Unlike pre-cut sheets, a coil of smooth FRP sheet enables continuous, efficient production.

Reduced Waste and Cost: Manufacturers can unroll and cut lengths precisely to panel size, dramatically minimizing off-cuts and material waste associated with fixed sheet sizes.

Enhanced Production Flow: It facilitates automated or semi-automated cutting and lay-up processes, streamlining the panel production line for higher output.

Superior Panel Lengths: It allows for the creation of extra-long panels without unsightly and weak horizontal seams, leading to a more aerodynamic, stronger, and better-looking truck body.

Easier Handling and Storage: Coils are often easier to store and handle in a factory environment compared to stacks of large, rigid sheets.

This format makes the smooth fiberglass sheet for composite panel production not just a better material, but a smarter, more efficient one.

The true genius of the single-layer solid fiberglass sheet is its exceptional compatibility with diverse core materials, acting as the universal, high-performance facilitator.

When bonded to XPS or PU foam cores, the smooth FRP sheet creates an "insulated fortress." The FRP skin provides a seamless, impermeable barrier against moisture, chemicals, and UV degradation—addressing the primary weakness of foam cores, which can be susceptible to water ingress and surface damage. In return, the foam core offers outstanding thermal insulation (critical for refrigerated trucks) and significant weight reduction. The smooth fiberglass sheet 1.5mm is particularly prevalent here, giving the panel enough facial strength to resist denting while maintaining excellent thermal efficiency.

For applications where ultimate strength and minimal weight are paramount, the partnership between the solid fiberglass sheet and an aluminum or aramid honeycomb core is unbeatable. The smooth FRP sheet forms a perfect, rigid facing that distributes loads efficiently across the honeycomb structure. The result is a panel with an exceptional strength-to-weight ratio, ideal for high-stress applications like large curtain-sider posts, doors, or flooring in lightweight trucks. The choice between smooth fiberglass sheet 1.2mm for ultimate lightness or 2mm for maximum facing stiffness allows precise engineering for the load case.

Moving beyond standard wall construction, this material enables innovative design solutions:

Seamless Integrated Roofing: Long coils of smooth FRP sheet allow for single-piece, curved roofs that shed water perfectly and have no leak-prone seams.

Hybrid Panel Construction: A manufacturer can use smooth FRP sheet 2mm for the lower 4 feet of a side panel (for impact resistance) and 1.5mm for the upper section (for weight savings) from the same coil, creating a functionally graded panel.

Mold-Less Fabrication: For custom or low-volume builds, the coil material can be laid over a temporary form or core structure and bonded in place, reducing the need for expensive male/female molds.

In conclusion, the range of solid smooth fiberglass sheets—available as smooth fiberglass sheet 1.2mm, 1.5mm, and 2mm in coil—is far more than just a inventory item for panel makers. It is the critical, enabling component that allows for the practical, high-performance marriage of protective skins and functional cores. By choosing the appropriate smooth FRP sheet 1.2mm, 1.5mm, or 2mm variant, engineers can dictate the face sheet performance, tailoring each composite truck panel to its specific duty. This smooth fiberglass sheet for composite panel use embodies a new era of material science application: one where simplicity (a single-ply, solid fiberglass sheet), format innovation (the coil), and strategic thickness selection converge to create smarter, stronger, lighter, and more durable commercial vehicles. It is not just a part of the truck; it is the foundational skin upon which reliability and efficiency are built.

Contact us:

Email: lzpanels@163.com

WhatsApp/Wechat: 008613702432446