- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

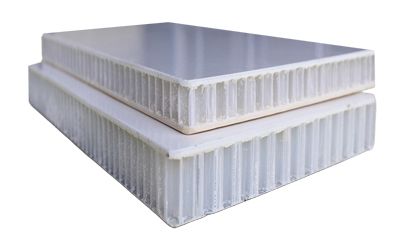

In the competitive world of refrigerated transport, the quality of truck body materials directly impacts performance, durability, and operational costs. The 2mm plain white FRP reinforced fiberglass panel has emerged as a leading solution for constructing high-performance refrigerated truck bodies. Designed in roll form for seamless integration with insulating cores like XPS foam, polyurethane, or honeycomb structures, this reinforced fiberglass panel is the backbone of durable and efficient sandwich panels used in cold chain logistics.

Below, we explore six key advantages of using 2mm FRP panel in refrigerated truck manufacturing, detailing why it outperforms traditional materials.

The plain FRP panel is reinforced with high-tensile fiberglass, ensuring superior strength while remaining lightweight. Unlike steel or aluminum, this white FRP panel does not dent, warp, or corrode, making it ideal for heavy-duty transport applications.

When combined with XPS foam or honeycomb cores, the 2mm reinforced fiberglass panel forms a rigid sandwich panel that withstands mechanical stress, vibrations, and impacts during transit. This structural stability ensures long-lasting performance, even in extreme conditions.

Refrigerated trucks require materials that minimize heat transfer to maintain consistent internal temperatures. The 2mm FRP panel, when laminated with insulating cores like polyurethane foam or honeycomb, creates an airtight barrier that prevents thermal leakage.

The plain FRP panel itself has low thermal conductivity, enhancing the insulation properties of the sandwich panel. This ensures energy efficiency, reducing refrigeration costs while keeping perishable goods fresh.

One of the biggest challenges in refrigerated transport is balancing durability with weight. The 2mm reinforced fiberglass panel is significantly lighter than metal alternatives, reducing the overall weight of the truck body.

By using FRP panels in sandwich construction, manufacturers can achieve a strong yet lightweight structure that improves fuel efficiency without compromising load capacity. This makes the white FRP panel a cost-effective choice for long-haul logistics.

The plain white FRP panel features a smooth, non-porous surface that resists bacterial growth, mold, and staining. This makes it perfect for food, pharmaceutical, and chemical transport, where hygiene is critical.

Unlike textured surfaces that trap dirt, the 2mm FRP panel can be quickly cleaned with mild detergents, ensuring compliance with food safety regulations such as FDA and EU standards.

Refrigerated trucks often transport seafood, dairy, chemicals, and other corrosive substances. Traditional metal panels can rust or degrade, but the reinforced fiberglass panel is inherently resistant to:

Saltwater corrosion (ideal for seafood transport)

Chemical exposure (acids, alkalis, cleaning agents)

Humidity & extreme temperatures

This durability ensures that the 2mm plain FRP panel maintains its integrity for years, reducing maintenance costs.

While the initial cost of FRP panels may be higher than some metals, their long-term benefits make them a smarter investment:

No painting or coating required – The white FRP panel retains its finish without fading.

Minimal repairs – Resists dents, rust, and UV damage.

Easy installation – Supplied in rolls for seamless lamination with core materials.

When used in sandwich panel construction, the 2mm reinforced fiberglass panel reduces lifecycle costs, making it a preferred choice for refrigerated truck manufacturers.

✔ Optimized for sandwich panel production – Compatible with XPS, PU foam, and honeycomb cores.

✔ Superior insulation properties – Enhances energy efficiency in refrigerated transport.

✔ Food-grade & chemical-resistant – Meets FDA, EU, and ISO standards.

✔ Lightweight yet durable – Reduces fuel consumption without sacrificing strength.

✔ Available in rolls – Easy to laminate and shape for custom truck body designs.

The 2mm plain white FRP reinforced fiberglass panel is revolutionizing cold chain logistics with its strength, thermal efficiency, and corrosion resistance. Whether paired with XPS foam, honeycomb, or polyurethane cores, this reinforced fiberglass panel delivers unmatched performance in sandwich panel construction.

For manufacturers seeking a reliable, cost-effective, and durable solution, the 2mm FRP panel is the ultimate choice. Upgrade your refrigerated truck bodies today with high-quality white FRP panels designed for excellence in transport efficiency and longevity.

By integrating plain FRP panels into your production process, you ensure better insulation, reduced maintenance, and superior load performance—making it the smartest investment for refrigerated transportation.

Our Contact Information:

Email: lzpanels@163.com

WhatsApp/Wechat: 008613702432446