- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

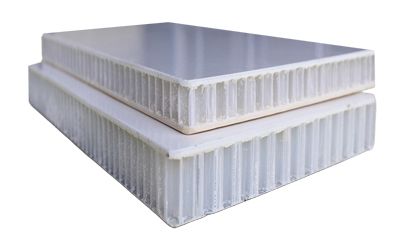

Fiberglass sheets, commonly referred to as GRP (Glass Reinforced Plastic) or FRP (Fiber Reinforced Plastic), have revolutionized modern industrial applications due to their lightweight, durable, and versatile nature. One increasingly popular application is their use as skin sheets in PP (Polypropylene) honeycomb panels for the construction of dry cargo truck boxes. These composite panels provide a highly effective solution for the logistics industry, balancing strength, durability, and cost-efficiency. Below, we delve into the features and advantages of using GRP/FRP sheets as skin materials, the role of PP honeycomb cores, and their synergistic benefits in truck box applications.

Fiberglass sheets are composite materials made by reinforcing resin matrices (e.g., polyester or epoxy) with glass fibers. This creates a material that is lightweight yet exceptionally strong, with numerous features tailored for truck box construction:

High Strength-to-Weight Ratio: GRP/FRP sheets deliver high mechanical strength without adding excessive weight to the truck. This improves fuel efficiency and load capacity.

Weather Resistance: The fiberglass sheets are highly resistant to UV radiation, temperature fluctuations, and moisture, ensuring they perform well under various environmental conditions.

Corrosion Resistance: Unlike traditional metals, GRP/FRP sheets do not corrode, making them ideal for long-term use in the transportation of goods.

Customizability: They can be manufactured in various thicknesses, textures, and finishes, including smooth or anti-slip surfaces, to meet different application needs.

Ease of Maintenance: GRP/FRP sheets are easy to clean and maintain, contributing to lower lifecycle costs.

The polypropylene honeycomb core, sandwiched between two GRP/FRP sheets, forms the core of the composite panel. This lightweight material provides numerous advantages:

Exceptional Compression Strength: The honeycomb structure efficiently distributes forces, offering high compressive strength without adding significant weight.

Energy Absorption: It provides excellent impact resistance, protecting cargo from external shocks during transport.

Environmental Friendliness: PP honeycomb is recyclable and eco-friendly, aligning with sustainability goals.

Thermal Insulation: Its low thermal conductivity enhances the thermal performance of truck boxes, keeping the interior temperature stable.

The combination of GRP/FRP sheets with a PP honeycomb core creates a composite panel that is far superior to traditional materials like plywood, metal, or plain plastic in various aspects:

Weight Reduction: The lightweight PP honeycomb core significantly reduces the panel’s overall weight while maintaining high strength, leading to increased truck payload capacity and improved fuel efficiency.

Structural Integrity: The rigid GRP/FRP skin sheets provide a tough outer layer that resists punctures, abrasions, and wear, ensuring the long-term structural integrity of the truck box.

Noise Reduction: The honeycomb core acts as a sound barrier, minimizing noise during cargo transport.

Enhanced Aesthetic and Functional Appeal: The smooth surface of GRP/FRP sheets can be easily painted or coated, offering branding opportunities and ensuring water-tight construction.

Cost-Efficiency: The panels require less maintenance and have a longer service life than traditional materials, reducing operating costs.

The unique properties of GRP/FRP skin sheets combined with a PP honeycomb core make them ideal for various applications within the dry cargo truck box sector:

Wall and Roof Panels: Lightweight panels reduce the overall weight of the truck body, increasing the payload capacity. Their high strength ensures the truck box remains rigid and stable during operation.

Flooring: Anti-slip FRP surfaces enhance safety, while the honeycomb core provides the necessary rigidity for load-bearing applications.

Doors: GRP/FRP-clad doors are lightweight, easy to open, and provide a robust barrier against theft and environmental factors.

5. Environmental and Sustainability Benefits

In an era where sustainability is paramount, GRP/FRP honeycomb panels stand out as an environmentally friendly solution:

Recyclability: Both Fiberglass GRP/FRP sheets and PP honeycomb cores can be recycled, reducing the environmental impact of truck body production and disposal.

Energy Efficiency: The lightweight design reduces fuel consumption in vehicles, contributing to lower carbon emissions.

Longer Lifespan: The durability of these panels means fewer replacements and less waste over time.

Fiberglass GRP/FRP sheets, when used as skin layers for PP honeycomb panels, provide a modern solution for dry cargo truck boxes that meets the logistics industry's demands for durability, efficiency, and sustainability. The synergy between the strong GRP/FRP skin and the lightweight PP honeycomb core ensures enhanced performance, reduced costs, and environmental benefits. As the logistics industry evolves, this composite material combination is set to play a critical role in advancing transportation solutions for decades to come.

If you are looking for a China manufacturer of Fiberglass GRP/FRP Sheets as Skin Layers for PP Honeycomb Panels in Dry Cargo Truck Boxes, please contact us.

Contact information:

Email: lzpanels@163.com

WhatsApp/Wechat: 008613702432446