- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

In the world of commercial vehicle bodybuilding, the quest for the perfect panel material is relentless. Among the myriad of options, one stands out for its remarkable versatility and performance: the plain white GRP fiberglass van panel. This material has become the cornerstone for constructing durable, efficient, and reliable box bodies for a vast array of applications. Unlike traditional materials, the GRP van panel offers a unique combination of strength, lightness, and impermeability that is perfectly suited for the demanding environments faced by commercial fleets. This comprehensive guide will explore the multifaceted nature of this material, delving into its composition, its pivotal role in both dry freight and refrigerated units, and the reasons behind its growing dominance in the industry. We will move beyond a basic overview to uncover the engineering principles and economic advantages that make it an unparalleled choice for modern logistics.

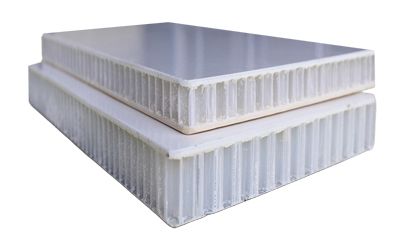

To truly appreciate the value of the GRP van body panel, one must first understand what it is. GRP, or Glass Reinforced Plastic, is a composite material formed by reinforcing a plastic matrix with fine glass fibers. This combination results in a product that inherits the best properties of its constituents: the flexibility and waterproof nature of the plastic resin, and the high tensile strength of the glass fibers. The resulting flat panel is not an end product but a superior starting point—a robust skin ready to be transformed into a high-performance sandwich panel.

The fundamental genius of using a flat Fiberglass van panel lies in its role as the foundational skin for a composite structure. On its own, the panel is strong and durable. However, its true potential is unlocked when it is permanently bonded to a core material, such as various foams (polyurethane, polystyrene) or PP honeycomb. This process creates a structural sandwich panel with exceptional properties. The GRP skins bear the tensile and compressive loads, while the lightweight core provides immense stiffness and resistance to bending, all while contributing significant thermal insulation properties. This synergy is what makes the Fiberglass van body panel so effective for building entire box bodies—from walls and roofs to doors.

The plain white GRP fiberglass van panel is not a niche product; it is a universal solution. Its adaptability allows it to meet the stringent requirements of diverse transport sectors, making it the go-to material for body builders and fleet managers alike.

For standard logistics and distribution, the dry freight van is the workhorse of the road. Here, the GRP panel for box body proves its worth through exceptional durability and low maintenance. The smooth, non-porous white surface is inherently resistant to rust and corrosion, a common failure point for metallic alternatives. It can withstand the bumps and scrapes of loading and unloading without denting, and its structural integrity ensures the box body remains square and true, protecting the integrity of the vehicle and its cargo. The bright white finish also contributes to a cleaner, brighter interior, improving visibility for workers and reflecting light to help maintain a more stable internal temperature.

Perhaps the most demanding application for any panel is in a refrigerated truck body. This is where the Fiberglass panel for box body truly shines. The composite panels built with GRP skins offer exceptionally low thermal conductivity, creating a highly efficient thermal barrier. This is critical for maintaining consistent temperatures, reducing the workload on the refrigeration unit, and minimizing fuel consumption. The impermeability of the GRP skin is also vital; it prevents moisture ingress, which can compromise the core's insulating properties and lead to panel delamination and structural failure. For transporting perishable goods, pharmaceuticals, or frozen products, the integrity provided by a white Fiberglass panel for box body is non-negotiable.

The choice of a white GRP panel for box body is both a practical and strategic decision. The color and material work in concert to deliver benefits that extend beyond mere structure.

The structural performance of the Fiberglass van body panel is a key driver of its popularity. GRP composites have a high strength-to-weight ratio, meaning they provide immense structural rigidity without adding excessive weight. This translates directly into increased payload capacity and improved fuel economy for the vehicle. Furthermore, GRP panels exhibit excellent fatigue resistance, meaning they can endure the constant vibrations and dynamic stresses of road travel without cracking or failing. This longevity ensures a longer service life for the entire box body, providing a superior return on investment.

The characteristic white finish of the white Fiberglass panel for box body is far more than a default color choice. It is a functional feature. White has a high albedo, meaning it reflects a significant amount of solar radiation. This reflective property helps to reduce heat absorption, which is crucial for maintaining lower internal temperatures in dry freight vans and significantly reducing the cooling load for refrigerated units. Additionally, the smooth, glossy surface is easy to clean and maintain, and it provides an excellent, bright base for company branding and graphics, ensuring a professional appearance that lasts.

When compared to traditional materials like aluminum or plywood, the GRP van panel presents a compelling case that goes beyond simple substitution.

Aluminum, while lightweight, is prone to denting and can suffer from fatigue cracking over time. Plywood is susceptible to moisture damage, delamination, and rot. The GRP van body panel effectively eliminates these weaknesses. It is more impact-resistant than aluminum and completely impervious to the rot and corrosion that plague plywood and metals. While the initial cost may be different, the total cost of ownership for a GRP-based box body is often lower due to drastically reduced maintenance, repair, and downtime costs over the vehicle's lifespan.

Investing in a body built with a Fiberglass box body panel is an exercise in long-term economic logic. The durability of the material leads to fewer repairs and a longer operational life. The thermal efficiency of refrigerated panels lowers energy costs. The lightweight nature increases payload and improves fuel efficiency. When these factors are combined, the choice becomes clear: the GRP panel for box body is not an expense, but a strategic investment in operational efficiency and reliability.

The utility of the plain white GRP fiberglass van panel is not limited to just the side walls. Its properties make it the ideal material for constructing every major component of a box body.

The side and front walls of a box body bear significant structural loads and are most vulnerable to impact. Using a GRP box body panel for these sections ensures a monolithic, strong structure that resists impact and weathering. The seamless nature of large GRP panels also minimizes joints, which are potential weak points for leaks and thermal bridging.

The roof of a commercial vehicle is exposed to the harshest elements, from UV radiation to heavy rain and hail. A roof made from a Fiberglass panel for box body is inherently waterproof and possesses excellent UV stability, preventing degradation and leaks. Its strength can easily handle snow loads and the occasional low-hanging branch.

Doors are the most frequently used and abused part of any box body. They must be lightweight for easy operation yet incredibly strong to maintain seal and security. A door constructed from a white GRP panel for box body offers the perfect balance. It provides the structural integrity needed to hold heavy locking mechanisms and maintain a perfect seal with the door frame, all while being resistant to the slamming and impacts of daily use.

The plain white GRP fiberglass van panel has unequivocally established itself as a superior material for modern box body construction. Its journey from a simple flat panel to the key component in advanced composite structures demonstrates the innovative spirit of the transport industry. Whether for a dry freight van traversing the city or a sophisticated reefer unit carrying temperature-sensitive goods across the country, the GRP van body panel delivers unmatched performance, versatility, and economy. As the demands for efficiency, sustainability, and reliability in logistics continue to grow, the role of this remarkable material will only become more central. For anyone specifying, building, or operating a commercial fleet, understanding and leveraging the benefits of the fiberglass van panel is no longer an option—it is a necessity for success.

Contact us:

Email: lzpanels@163.com

WhatsApp/Wechat: 008613702432446